Departments

Graphic design department

Qualified personnel develop graphic layouts and optimise them for printing in terms of looks and functionality. We always find the best solution for every type of packaging.

Pre-printing department

We take the greatest care to produce packaging that is both unique and versatile by choosing the most suitable technology in conjunction with the customer, whether rotogravure or flexography.

Printing department

This is where the most important part of the process is performed – the printing itself. We have 2 rotogravure printing machines (10 colours) and 2 central drum flexographic presses (one 8 and one 10 colours).

We can also add special finishes like the application of matte varnish.

All our printing machines are equipped with continuous print quality control systems.

Laminating department

Many types of packaging need to be laminated, either for aesthetic or for product preservation purposes. We have three laminating machines, one combined solventless/solvent machine and two solventless machines.

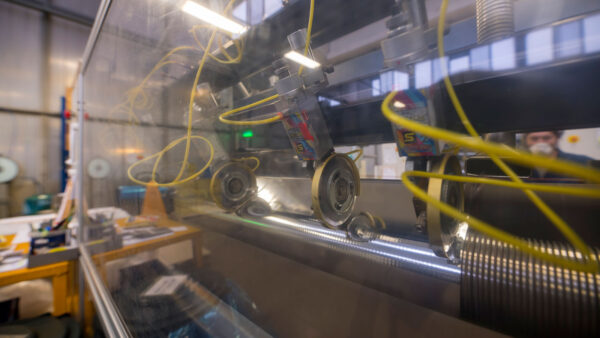

Slitting department

This is where the printed film is cut to the required size. The department is equipped with 4 machines with the latest cutting and rewinding systems.

Printing cylinder warehouse

A large warehouse contains the cylinders used for rotogravure printing, allowing to quickly satisfy every customer need.

Raw material warehouse

Our 4000 m² warehouse (always well stocked) provides a ready supply of a wide range of materials for the production of all kinds of packaging, from the simplest to the most complex.

Quality laboratory service

The laboratory is equipped with tools and technologies to carry out verification and monitoring activities, from the raw material to the finished product, according to a defined analysis plan. All this ensures continuous monitoring of all phases.

The Company has certified its Quality System according to UNI EN ISO 9001 standards.

- 2 Gas chromatographs

- Bar Code Control – REA – EAN

- 2 Dynamometers

- Welders and Brugger

- Spectrodensitometer

- FT – IR spectrophotometer